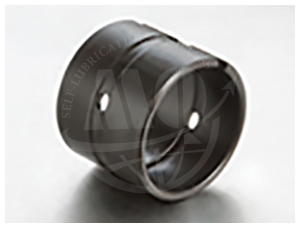

Bimetal Bushing based on high-quality low carbon steel back as substrate and bronze alloy on the surface. After several high-temperature sintering and density and rolled copper and steel bimetallic strip coiling, the product can withstand medium speed and high impact load under bush and thrust washer and so on many kinds of USES.

It is a good choice for bearings in the radial direction and can withstand medium load and shock load. In addition, it can also withstand abnormal working conditions and can be used for different applications such as Truck, transmission cases, Textile machines, car chassis, steering knuckle, trunnion shaft, leaf spring, motorcycle clutches, wear plating of gear pumps and hoisting machine etc.

The forged bushings were metallographically investigated to ensure the quality of the joining zone, especially at the interface zones between steel and aluminum. A metallurgical bond between the two materials was achieved by a combination of tailored forming technology and centrifugal casting.

The forged bushings were made from steel and aluminum by using a closed-die-forging process. Depending on the forging temperature and the speed of rotation, the resulting bushings can be shaped by a variety of methods. For example, a crucible forging method is used to form the bushings by pouring metals into a mold and subsequently heating them up. Another method is a compound forging. The latter is a complex and demanding process, which requires the use of a large forging die and a high-quality forming tool.