At present, the product has been used in metallurgical caster, train stent, rolling equipment, mining machinery, ships, gas turbines and other high temperature, high load, low speed and other occasions.

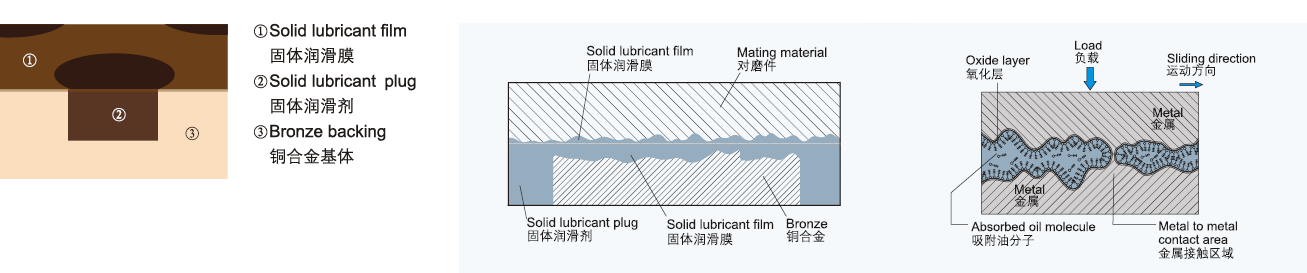

MQ650# materials consist of highly wear-resistance copper cast alloy whose sliding surfaces are evenly provided with a certain percentage of solid lubricant plugs according to work condition, high-strength copper alloy provides a high load-bearing capacity and the solid lubricant can be formation of low friction film. Under technical dry running conditions, the bearing surface is designed with thick running-in film which enables the solid lubricant to be transferred to the counter material at the first contact.

When the mutual friction occurs between two non-lubricated surfaces. the two contacts with the unevensurface of the peak by the shear. stick-slip and plastic the conventionallubricant will be more and more squeezed out of the contact area with increasing surface which formed the dry friction or boundary lubrication. With MQ650. the lubrication is etfected by the sliding material itself. The solid lubricant is released from the fnction material by micro-movement This gives the sliding partners under heavyloads The embedded solid lubricant plugs can be continuously provided to the friction surface to reduce friction resistance and wear, thus make the bearing can be worked under low wear rate and long.life service.

1. No need to oil installations, the filling hole processing tank

The cost of oil installations, processing fees, assembly fees, the extra cost and time savings can significantly reduce manufacturing costs.

2. Lower operating costs

Substantially reduce the use of lubricants and equipment maintenance costs, while also eliminating the risk caused due to insufficient oil supply.

3. The shortening of design time

Non-oil can make the design, structure, and greatly simplify and reduce costs, save design time and to obtain significant results, in addition, the use of self-lubricating bearings can also improve the mechanical properties and extend the service life and higher reliability.

4. Lubricating oil recycling and environmental protection

No need to waste oil recycling, are environmentally friendly.

JDB (500#SP), self-lubricating bearing parts of the machinery industry, the use of certain generalized. In order to make the mechanical drive is operating normally, a lot of effort. The bearing area is divided into Rolling and plain bearings. Sliding bearings in high-load movement, foreign substances, temperature, fuel, maintenance, imperfect circumstances, can cause galling. Like sliding bearings can not be used under harsh conditions, the solid inlaid metal self-lubricating bearings, wear resistance, resistance to galling, to play the bearings of the due performance, the role of mechanical performance and maintenance-free.

1. Properly and simply designed, widely used;

Oil offering system is an energy waste and time waste set in mechanical design. There is no needs for considering the oil-putting set in design when using the solid lubricant bushing so it can save the oil-putting equipment and at the same time it also design the solid-lubricant-inlaid bushing into alt kinds of shapes in order to meet various needs in special places. Using solid-lubricant. inlaid bushing can reduce the costs of the machinery mending and the oiI in wide range.

2. Being used without oil;

Because of the linear coefficient expansion of the solid lubricant is bigger than that of the metal basement, when the solid-lubricant-inlaid bushing starts to operate, the oil film can transfer to the corresponding friction set to make out self-lubricant. So the solid-lubricant-inlaid bushing can be used in places where the oil or grease cannot be added. It can make out the self-lubricant function even though under high load conditions.

3. Low cost for usage;

Traditional mechanical design asks for frequently aiding oil and checking if the oil watch and the offering set are through in certain period. Because adding oil at regular intervals causes the pollution to the machine itself and the nearby surroundings and increase the maintenance cost. And when the self-lubricant is made out, it can not only make the surroundings clean but also decrease the cost of using the Iubricant. 4. The superior functions can be brought into play under high load and low rotati ng speed.

The solid-lubricant-inlaid bushing is based on the high intensity brass that is centrifuge cast. And then make out the loading function. Use special graphite that has good self-lubricant properties as lubricant to make out the self-lubricant so that the bushing has included all of their advantages. It can still bring the superior properties into play even under high load and low rotating speed.

5. The wear resistance can be brought into play even ln places the oil film form into difficulties because of the reciprocating and rocking movement, starting and stopping;

The arrangement principle of the lubricant of the solid-lubricant-inlaid bushing is to ensure that all the parts of the corresponding friction sets have the lubricant function in the operating procession. So the arrangement place 0f the lubricant should be depended upon the operating direction of the corresponding friction sets.

6. Superior chemical resistance and corrosion resistance;

Bushings inlaid with solid lubricants,graphite and PTFE lubricants. It has steady molecule structures. The metal basement can be chosen according to the different chemicaI resistance and corrosion resistance of the metal appliance. So the solid-lubricant-inlaid bushing has the superior chemical resistance and corrosion resistance.

7. The products is more competitive, comparing to the similar kinds of products, comparing to the similar products. Such products feature longer working life and good performance but rarely require maintenance.

1. Use standard designation when designing if possible;

2. Note if there are any foreign matters on the surface when assembling;

3. Do not erase the black or grey phenomenon on the sliding surface caused by the oil film that is formed by the solid lubricant after using;

4. It is good for mechanical operation and running if lay the lubricant on the corresponding friction set before installing;

5. Pressing should be carried out slowly when installing. Do not beat in the event of damaging the bushing or causing the distortion to the bushing;

6. Using proper material in different parts when designing in order to enhance the mechanical properties and prolong the service life of the bushing;

7. It would be better to fix with bolt in high load and reciprocating motion;

8. It is recommended to use stainless steel or plate chrome on the surface of the corresponding friction shaft when working in the water or in the sea.

| Standard | JDB Casted Bronze (MQ650)) | JDB -1 Bronze (MQ650S1)) | JDB -2 Bronze (MQ650S2) | JDB -3 Bronze (MQ650S3) | JDB -5 Bronze (MQ650S4) |

|---|---|---|---|---|---|

| Material | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | CuZn25Al5Mn4Fe3 |

| Density | 8.0 | 8.9 | 7.8 | 8.9 | 8.0 |

| Hardness HB | >210 | >70 | >150 | >95 | >250 |

| Tensile strength N/mm² | >750 | >200 | >600 | >260 | >800 |

| Yield strength N/mm² | >450 | >90 | >260 | >150 | >450 |

| Elongation % | >12 | >15 | >10 | >8 | >8 |

| Coefficien of linear expansion 10-5/℃ | 1.9 | 1.8 | 1.6 | 1.8 | 1.9 |

| Limit Temp ℃ ℃ | -40~+300 | -40~+400 | -40~+400 | -40~+400 | -40~+150 |

| Max.load N/mm² | 100 | 60 | 50 | 70 | 120 |

| Max.speed (Dry) m/min | 15 | 10 | 20 | 10 | 15 |

| Max.PV N/mm² *m/min | -40~+300 | -40~+400 | -40~+400 | -40~+400 | -40~+150 |

| Compression of permanent deformation 300N/mm² | <0.01 | <0.05 | <0.04 | <0.05 | <0.05 |

* Big damand with special materials is available

| Material Codes |

China GB1176-87 |

Intenational ISO 1338 |

Germany DIN |

Japan JIS |

America ASTM(UNS) |

England BS |

Italy JM |

Applicable conditions |

|---|---|---|---|---|---|---|---|---|

| JDB Casted Bronze | ZCuZn25Al5 Mn4Fe3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | JM18-1 | High-load,low speed Commonly used |

| JDB -1 Bronze | ZCuSn5 Pb5Zn5 |

GCuPb5 Sn5Zn5 |

DIN1705 G-CuSn5ZnPb |

H5111 BC6 |

B30-92 C83600 |

LG2 | JM1-15 | Mid-load,low speed Commonly used |

| JDB -2 Bronze | ZCuAl9Fe4 Ni4Mn2 |

GCuAl10 FeNi5 |

DIN17656 G-CuAl10Ni |

H5114 AlBC3 |

B30-92 C95500 |

AB2 | JM7-15 | Mid-load,mid-speed, Commonly used |

| JDB -3 Bronze | ZCuSn12 | G-CuSn12 | CAC503B | B30-92 C90800 |

PB2 | JM3-15 | Mid-load,low speed, Commonly used | |

| JDB -5 Casted Bronze (high hard) | ZCuZn25Al5 Mn4Fe3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | JM18-1 | Over high load,low speed, High load used |

| Lubricant | Features | Typical application |

|---|---|---|

| SL1 Graphite+add |

Excellent resistance against chemical attacks and low friction, Temp limit 400℃ | Suit for general machines and under atmosphere |

| SL4 PTFE+add |

Lowest in friction and good of water Lubrication,Temp limit 300℃ | Ship, hydraulic turbine, gas turbine, etc. |

Jiashan Minqin Oilless Bearing Co., Ltd. a China Solid Oilless Bushings Manufacturers, set up May.2007. As professional wholesale Solid Lubricants Bushing suppliers, Minqin has high-precision equipment, a high level of management team, and a high-quality workforce, and constantly improves the production process and refinement management platform, in strict accordance with the global quality certification system to do every detail for the industry to provide quality JDB650 Solid-lubricants Oilless Bushings (MQ650) products.