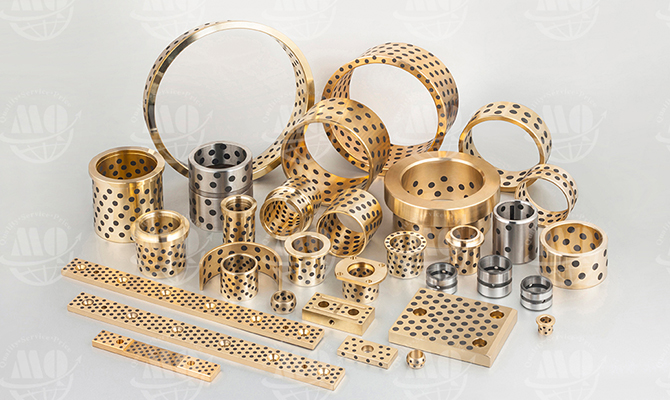

Bronze wrapped bushings are designed to withstand heavy loads and are shock-resistant. They have lubrication pockets on the entire sliding surface, which helps to reduce friction at startup and during operation.Oil-impregnated bushings rely on capillary action to create a lubricating film. However, oscillating motion and low speeds can inhibit this process.Bronze bushings are more durable than other types of bearings and can withstand high load levels. This makes them a good choice for heavy-duty industrial machinery applications. They also have good anti-wear properties and can withstand corrosion and impact.It wrapped bronze plain bearings are made from a cold formable bronze alloy with diamond-shaped lubrication indents on the sliding surface to stock grease. This allows them to rapidly build up a lubrication film during the start movement and thus reduces the start friction.

They are also insensitive to contaminated environments and are suitable for use with shock loads or vibrations. Moreover, they can also be made in customized dimensions and designs to suit particular applications. They are also able to support both linear and rotating movements, as well as radial and axial loads in one direction. This versatility makes them an ideal solution for a variety of applications across many industries. Besides, they are easy to install, requiring only a simple press fit into the housing.Bronze is a durable material that resists corrosion and offers high resistance to impurities. This makes it ideal for harsh environments that need a durable bearing to withstand constant use and vibrations. It also offers high load capacity and good wear resistance.Rolled Bronze bushings have diamond-shaped lubrication pockets rolled on the surface that serve as reservoirs to gradually release lubricant during operation. This allows them to last longer than conventional bronze bearings that need to be re-lubricated frequently.

They are a great choice for dirty environments where the level of contamination can make re-lubrication difficult. They are also more compact and less expensive than machined bronze bushings. They can take radial and axial loads. They are ideal for flange and cylindrical bearings, thrust washers and half bushings. They are often used in a variety of industries such as construction, agricultural and industrial machinery. This type of bushing can also be machined with various spherical rolling oil grooves and diamond-shaped indentations to suit different applications.Bronze based self lubricating bearings can come in a range of forms. Each has its own unique advantages and benefits. Bronze bushings are typically lubricated with a series of diamond shaped oil pockets on the surface of the sliding surface. The pockets are filled with grease initially, then act as reservoirs that gradually release lubricant over time to maintain smooth operation. These types of bronze bushings are insensitive to contamination, making them ideal for machinery that operates in dirty environments.

In some cases, the bronze based self-lubricating bearing may be combined with a steel backing or other metal material to add strength and stability. The result is a hybrid that can handle heavy loads and high speeds. These types of bronze based self-lubricating bearings are commonly used in the automotive braking system industry and other equipment that requires high load capacity and slow speed application.Bronze bushings are easily press-fitted into their housing, which makes installation fast and easy. This also helps to ensure a tight fit, which reduces the risk of damage and improves durability. They are suitable for radial and axial loads, and can be used in various shaft sizes and load capacities.Oil-impregnated bronze bearings rely on capillary action to create a film of lubricant on the surface of the bearing, but high speeds, vibration, and intermittent use can inhibit this process. In addition, the surface of the bushings can dry out, causing squeaking and an increase in friction.