How are oil-free bearings produced? Bearings are precision parts and are used in various equipment with oil-free bearings. Therefore, to ensure the normal use of the equipment, it is necessary to ensure that the safety function of the bearing is excellent, so the product must be well checked. .

Oil-free bearing production technology and principle:

Due to the requirements of production technology, some key equipment of the Self-lubricating Bearing Division of the Industrial and Mining Corporation operates under extremely harsh working conditions. Because the equipment is heavy, the ambient temperature is high, the dust is large, or the air contains acidic corrosive gases such as CO, SO2, etc., many questions are raised about the smoothness of the equipment, and the friction and wear are severe. So far, most of the above-mentioned domestic companies still follow the traditional oil, Grease is smooth, but in fact, these working conditions have exceeded the range of oil and grease smooth sliding bearings, and it is easy to bite or bite the bearings and other conflicting pairs, causing severe wear and damage to parts, often causing Equipment out of service. In order to produce continuous operation, in addition to requiring multiple types of equipment to be installed in the initial design, a large number of maintenance personnel must also be invested. Severe constraints on the improvement of productivity, and huge consumption of spare parts and energy, have become the main obstacle to the development of production. Car manufacturing, cement production, petrochemical and other companies have all put forward the requirements of supplying special smooth materials under complex working conditions. For this reason, the research on inlaid self-smoothing composite material highlights its own characteristics in material formulation and preparation technology, and the material function has reached the international advanced level, which has solved the smoothing problem under special working conditions for the company and brought significant benefits. economic and social benefits. However, due to various reasons, more domestic companies did not choose it, and the above situation still exists.

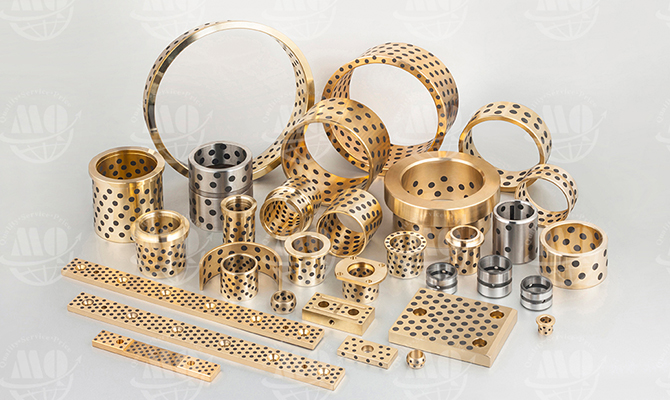

Inlaid self-lubricating composite material is a new type of extreme pressure-resistant solid lubricating material, which is composed of a metal substrate and a solid lubricating agent paste embedded in the holes or grooves of the substrate. The metal substrate bears most of the load during the conflict. After the collision, the solid lubricant in the hole or groove is transported or reversed to the collision surface, forming a smooth and outstanding, firmly attached and evenly covered solid transport film on the collision surface, which greatly reduces the friction and wear. As the conflict progresses, the embedded solid lubricant is continuously supplied to the conflict surface, ensuring excellent smoothness during long-term operation.

Jiashan Minqin Oilless Bearing Co.,Ltd. is an Oilless Bearing Manufacturer and Bronze Wrapped Bushing and other products, welcome to visit our official website.