1. It should be determined whether there are bumps, protrusions, etc. on the mating surfaces of the shaft center and shaft shell. If so, use oil grindstone or fine sandpaper to remove them.

2. Confirm whether there is dust or mold sand attached to the surface of the bearing shell.

3. In order to avoid bumps during installation, a small amount of lubricating oil should be applied to the surface of the shaft and shaft housing. When installing the bearing on the shaft center, force must be applied to the inner ring, and when installing the bearing on the bearing shell, force must be applied to the outer ring. When applying force to the bearing, be careful to make the force go down vertically and evenly, and the bearing will be injured by eccentric hits, so try to avoid eccentric hits.

4. The retainer and sealing plate of the oil-free bearing must not be forced. The installation method of using a hammer and a casing is a commonly used method because it will damage the bearing, so do not hit it directly. It should be struck with the sleeve in the middle, and the hammer should be struck lightly. In the mechanical structure, when the inner and outer rings are tightly fitted, a backing plate should be used, so that the force can be applied to the inner and outer rings at the same time. If only the inner ring is press-fitted, the force must be pressed into the outer ring by the balls, thus causing scars on the raceway surface.

5. When installing a bearing with a large margin on the shaft, the method of heating the bearing to 80-90 degrees in clean oil to expand the inner diameter is widely used. Considering that the hardness of the bearing will be reduced due to overheating, it must not exceed 100 degrees. At this time, the bearing must be suspended by steel wire, or placed on the wire guide or support plate, not on the bottom of the groove. When the bearing reaches the desired temperature (below 100 degrees), it should be taken out of the groove immediately and put into the shaft quickly. The bearing will shrink as the temperature drops, and sometimes there will be a gap between the shoulder and the end face of the bearing. Use a tool to compress the bearing in the axial direction.

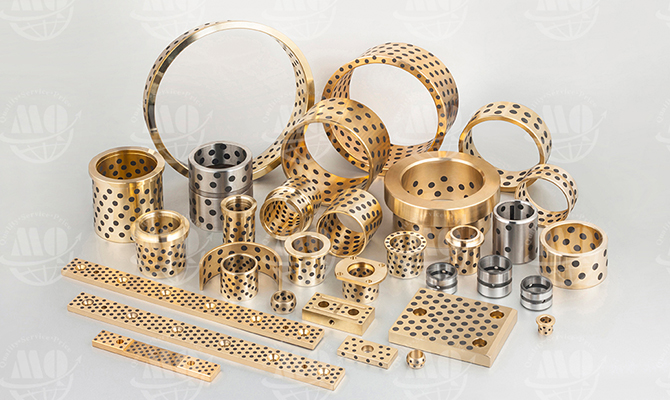

This oil-free bearing installation instruction is equivalent to a part of the oil-free bearing product manual, and we also need to understand it, so as to better use and protect the oil-free bearing. And our neglect may damage the bearing and affect the service life of the bearing.

Jiashan Minqin Oilless Bearing Co.,Ltd. is an Oilless Bearing Manufacturer and Wrapped Bushing and other products, welcome to visit our official website.