The damage forms of sliding bearings include wear, melting, peeling off Oilless Sliding Bearing and cracks on the working surface. The main reason for these defects is that the oil film is destroyed for some reason, resulting in direct friction between the journal and the bearing surface. For the defects of different bearing forms, the repair methods are also different.

(1) The repair of the integral sliding bearing generally adopts the method of replacing the shaft sleeve. (2) The split sliding bearing is slightly worn, and the Oilless Sliding Bearing is treated by adjusting the gasket and re-scraping. (3) For the inner column and outer tapered sliding bearing, if the working surface is not seriously scratched and only for precision trimming, the clearance can be adjusted by the nut; when the working surface is severely scratched, the spindle should be disassembled, and the bearing should be scraped again. , to restore the matching accuracy of the sliding self-lubricating bearing. When there is no adjustment allowance, the spraying method can be used to increase the diameter of the outer cone of the bearing, or the conical surface of the small end of the bearing can be removed by car, and the length of the thread can be lengthened to increase the adjustment range. When the bearing is deformed and worn seriously, it must be replaced. (4) For multi-piece sliding bearings, when the working surface is slightly scratched, the inner surface of the bearing can be polished and repaired by grinding. When the working surface is burnt or worn seriously due to holding the shaft, the inner surface of the bearing can be repaired by scraping and grinding.

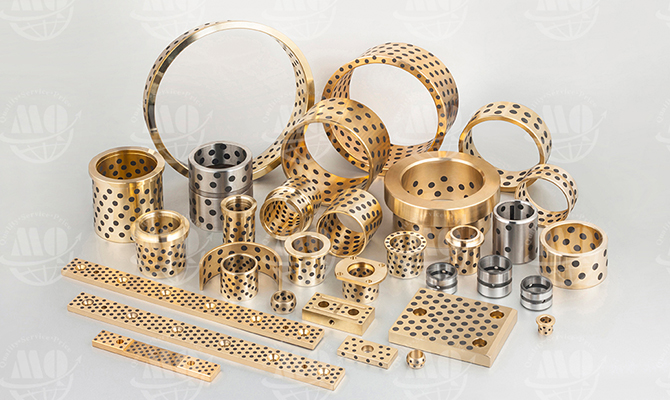

Jiashan Minqin Oilless Bearing Co.,Ltd. is Oilless Bearing Manufacturers and Lubrication Bushing and other products, welcome to visit our official website.