In order to solve the lubrication problems of high temperature, low speed, heavy load, large dust, water shower and shock vibration in mechanical equipment, oil-free self-lubricating bearings are selected.

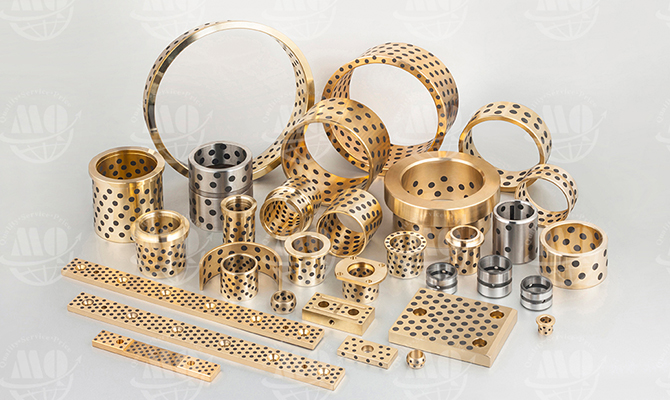

1. The structure of the bearing Self-lubricating bearings are developed on the metal friction surface of the bearing matrix in orderly arranged holes of appropriate size, and embedded with molybdenum disulfide, graphite, etc. to make a composite self-lubricating block embedded in the metal sleeve, made of composite For bearings, the friction area of solid lubricants reaches 25-65%. The solid self-lubricating block can work normally at a high temperature of 280°C. However, due to its low mechanical strength, weak bearing capacity, and easy deformation, it can be suppressed by embedding it in the metal hole groove, forming a metal part to carry the load, and a self-lubricating block to lubricate. The lubrication mechanism of this self-lubricating bearing is that during the sliding friction process between the shaft and the sleeve, a part of the self-lubricating material molecules are transferred to the metal surface of the shaft, filling up the small unevenness, and forming a relatively stable solid lubricating film , causing the friction between the solid lubricating films to prevent the adhesive wear of the shaft and the sleeve. This rational combination combines the complementary advantages of copper alloys and non-metallic wear-reducing materials, and is especially suitable for movement ranges in oil-free, high-temperature, high-load, low-speed, anti-fouling, anti-corrosion, and strong radiation environments, as well as It is used under special working conditions where it is soaked in water or other solutions and cannot be lubricated at all.

2. The ratio of the area occupied by the self-lubricating block to the surface area of the self-lubricating block is related to the operating speed and bearing strength. The operating speed is low; the bearing strength is high, and the area occupied by the metal should be larger. For example, the area occupied by the self-lubricating block of the walking wheel bearing of the ingot-grabbing trolley is about 25%, and the bearing of the rotating shaft of the ingot pulling mechanism must be fully lubricated, and the pressure bearing strength is not large, and the area occupied by the self-lubricating block is about 65%.

3. Technical requirements for bushing materials. The bushing should be made of alloy copper. The bushing should have high hardness and generally need heat treatment, and its hardness should not be lower than HRC45.

4. The geometric shape and inlay requirements of the self-lubricating block. The shape of the self-lubricating block has two types: cylindrical and rectangular. The self-lubricating block can be cylindrical according to the size of the occupied area, and vice versa. Regardless of the shape, it must be firmly embedded to prevent it from falling off during operation.

5. The clearance between the bush and the shaft The linear expansion coefficient of the self-lubricating block is about 10 times that of steel. In order to adapt to the temperature change of the bearing, the gap between the shaft and the bushing is increased from 0.032-0.15MM to 0.45-0.5MM from the original four-stage dynamic fit (D4/DC4) of the metal parts. The self-lubricating block protrudes from the bushing metal by 0.2-0.4MM on the side of the friction pair. In this way, the bearing will be fully lubricated during the initial running-in period of the bearing operation, reducing the power consumption of power dragging.

Jiashan Minqin Oilless Bearing Co.,Ltd. is Oilless Bearing Manufacturers with Solid Lubricants Bushing and other products, welcome to visit our official website.