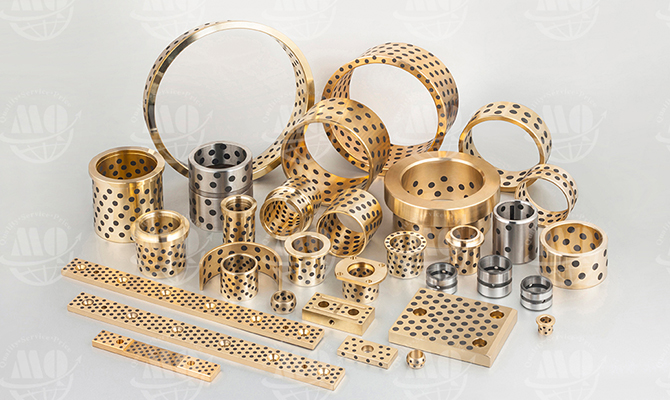

A

solid lubricant bushing is a type of bushing that combines a thermoplastic polymer and reinforcing fibers with an additive that releases a solid lubricant as soon as relative motion and contact occur between the bushing and shaft.There are a variety of solid lubricant bushings available for various applications and operating conditions. Understanding the load, environment, temperature and speed (LETS) can help ensure proper lubrication for longer bearing life.Self-lubricating solid lubricants bushings are a maintenance-free solution that can be applied in several applications. They are particularly suitable for equipment where lubricants could be contaminated or not available at all times.

These materials have been developed to help improve equipment and process efficiency. They help reduce energy loss and wear and tear on moving mechanical assemblies (MMAs).Unlike traditional lubricated bushings that require an oil film to prevent metal-to-metal contact, self-lubricating bushings transfer their lubricants as soon as they are set in motion. The lubricants are embedded as microscopic particles in millions of tiny chambers within the fiber-reinforced material.In addition, these lubricants are released continuously during movement and never become pressed out of the bushings. This allows them to provide continuous lubrication, which helps lower the friction coefficient between bushings and their mating surfaces.

The use of solid lubricants in mechanisms is an important solution to the challenge of preventing rust and corrosion while minimizing wear. Unlike fluid lubricants, which are squeezed out of the contact zones by evaporation, creep, or centrifugal motion, solid lubricants are contained in the critical contact regions.Various metal salts, such as boron nitride and polytetrafluorethylene (PTFE), are useful in solid lubricant applications because of their high chemical stability and ability to operate at a wide range of temperatures. These lubricants are often combined with other materials that offer additional strength, such as ceramics and composites.Another tribologically beneficial solid lubricant is a coating of noble metals, such as Ag and Au, which exhibit low friction and wear rates when tested in pin-on-flat contact with a light mineral oil at 150 ksi Hertzian stress. These coatings also have a lower CoF than uncoated part surfaces.

Solid lubricants that form a stable film at a temperature higher than 1000 degC have been investigated, with excellent results. These include CoCrW alloys with LaF3 and Ag as additives, which exhibited increased tribological properties at HT when tested in a ball-on-disk tribometer.Oil-impregnated solid lubricants bushings are a type of composite metal bearing. They are similar to standard PM bearings, except they rely on a capillary action to create and maintain a lubricating film rather than using a liquid lubricant.In order to create a lubricating film, these bearings must operate at high speeds and rotational motions. These requirements can cause them to wear out faster than other types of self-lubricating bronze bushings.