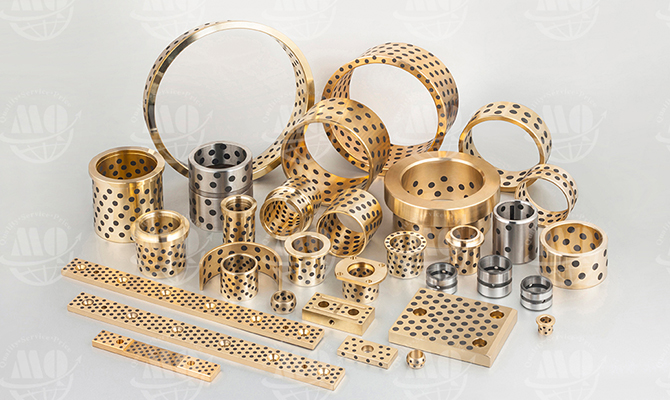

Lubrication Bushing

As the name suggests, a lubrication bushing is designed to provide protection from friction and wear. It does this by reducing the contact pressure between moving parts and minimizing friction that can lead to breakage.

Self-lubricating PTFE composites offer many advantages over traditional lubrication methods. They help to control friction between bearing surfaces and sleeve, resulting in increased service life and lower maintenance costs.

They can be used in applications where high temperature or heavy load requirements are a concern and where the performance of oil-impregnated bearings does not meet these needs.

The PTFE bushing has a solid lubricant embedded in the fiber-reinforced material that is automatically released during movement. The solid lubricant is incorporated into the millions of microscopic chambers in the fiber-reinforced material.

It also features geometric patterns to distribute stress more evenly throughout the materials. These two key design components make self-lubricating bearings a great option for a variety of industries and applications.

Typical application examples include hydraulic connections, excavator buckets and power lifts for tractors. Whether it’s for agricultural, construction or forestry machinery, these products are engineered to keep your equipment running efficiently and reliably for a long time to come.

If your vehicle has a suspension rubber bushing, it is essential to lubricate them periodically. Without lubrication, these bushings will experience friction and wear which can cause them to break down or become noisy.

A

lubrication bushing, also known as a bearing, is a type of mechanical component that is used to reduce friction between two moving parts. It is a cylindrical device that is placed between two metal surfaces to allow them to move smoothly against each other. There are several benefits of using a lubrication bushing:

Reduces friction: The primary benefit of using a lubrication bushing is that it reduces friction between two metal surfaces. This helps to prevent wear and tear on the parts and can prolong their lifespan.

Smooth operation: By reducing friction, a lubrication bushing can also help to ensure smooth operation of the machinery or equipment that it is being used in. This can lead to improved performance and efficiency.

Noise reduction: Another benefit of using a lubrication bushing is that it can help to reduce noise levels in the machinery or equipment. This is because the bushing helps to absorb vibrations and other types of noise.

Low maintenance: A lubrication bushing requires very little maintenance, which can help to save time and money in the long run. They are designed to withstand heavy loads and can operate for long periods without needing to be replaced.

Versatility: Lubrication bushings are available in a wide range of sizes and materials, which makes them versatile and suitable for use in a variety of applications. They can be made from materials such as bronze, steel, and plastic, depending on the specific requirements of the application.

Overall, lubrication bushings are an important component in many types of machinery and equipment. They help to reduce friction, ensure smooth operation, and require very little maintenance, making them a cost-effective solution for many industries.