The

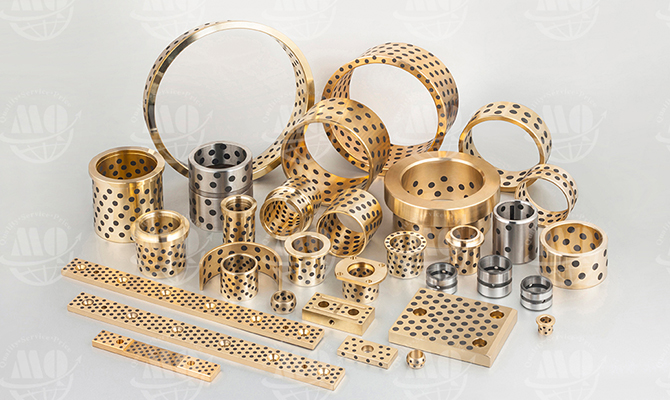

Solid Oilless Bushing is a bearing technology that relies on the formation of a solid lubrication film within the hole. This means that no oil is needed to lubricate the bushings, and this allows them to operate in environments that would otherwise not be suitable for oil-based bearings.These components are made from a variety of materials depending on the application and environment they’re going to be used in. This makes it important to understand the different properties that these bushings have so that you can ensure they perform as well as possible in your specific application.Bronze solid oilless bushings are a great option for applications that are exposed to harsh environments. They are corrosion resistant and have a longer lifespan than other types of bushings.

They also require little to no maintenance compared to traditional oil-based bushings. Moreover, they provide unique advantages such as high-temperature resistance and low friction.Several companies specialize in producing bronze self-lubricating bushings for industrial applications. They offer a variety of options to meet different design needs.These bearings are manufactured using a cast bronze base with a layer of solid lubricant. The lubricant is embedded to provide an excellent self-lubricating performance.They are suitable for a variety of applications including rotary and rolling mills, mining machinery, and industrial equipment. They also feature superior wear resistance and oxidation resistance.Stainless steel solid oilless bushings are ideal for heavy duty and high-temperature applications. They have a hardened layer of surface coating that helps prevent corrosion while allowing smooth movement between two surfaces.

They can withstand a large amount of load and provide consistent performance without the need for any additional lubricants. This helps users save on operating costs and maintain a clean environment.In addition, they are also resistant to harsh environments such as seawater and humid conditions. These factors make them a popular choice for many industries and machines.316L stainless steel is an excellent choice for these types of bearings because it offers superior resistance to corrosion and pitting. Additionally, it is capable of working in a wide range of temperatures and can be used in environments with chemicals and salts.Brass solid oilless bushings are designed to help reduce friction between a shaft and an underlying component. They are a cost-effective alternative to other types of bearings and can be used in harsh environments due to their abrasion-resistant design.

These components are made from a sintered bronze material with a graphite coating that acts as a self-lubricant. The combination of these two materials helps to reduce friction between moving parts and improve heat dissipation.In addition to its ability to reduce friction, this type of bushing also provides superior vibration dampening capabilities compared to other designs. It is an excellent choice for applications involving heavy loads or those that require energy absorption to dampen noise generated by moving parts within automated manufacturing systems.These components are available in a variety of sizes, types and materials to fit the needs of your specific application. Standard designs include straight guiding bushing, collar guiding bushing, thrust washer and slide plate.A Solid Oilless Bushing is a bearing component used to support moving components without the use of lubrication. They are commonly used in machinery that cannot be oiled or where lubrication may cause carbonization.

Compared to conventional bushes, oilless bearings require little wear and do not consume kinetic energy due to friction. This helps reduce maintenance costs and improves reliability.Power transformers are among the most common applications for bushings. Over the years, OIP bushing suppliers have made design changes aimed at slimming down porcelain housings in order to make them more portable and easier to install in transformers.As well as offering these benefits, the slimmer profiles mean that there is less space for the oil within the bushings themselves and thereby less risk of leakage or fire. This is a welcome development for transformer manufacturers and end users alike.