Materials commonly used for

oil-free bearings include:

Polytetrafluoroethylene (PTFE): PTFE is a polymer material with excellent self-lubricating properties. It has a low coefficient of friction and good wear resistance and is suitable for low to medium loads and low to medium speed applications.

Polyetherketone (PEEK): Polyetherketone is a high-performance engineering plastic with excellent wear resistance, high temperature resistance and chemical stability. It is suitable for high temperature, high speed and high load applications.

Polyimide (PI): Polyimide is a high-temperature wear-resistant material with excellent chemical resistance, abrasion resistance and heat resistance. It is suitable for applications in high temperature, high speed and corrosive environments.

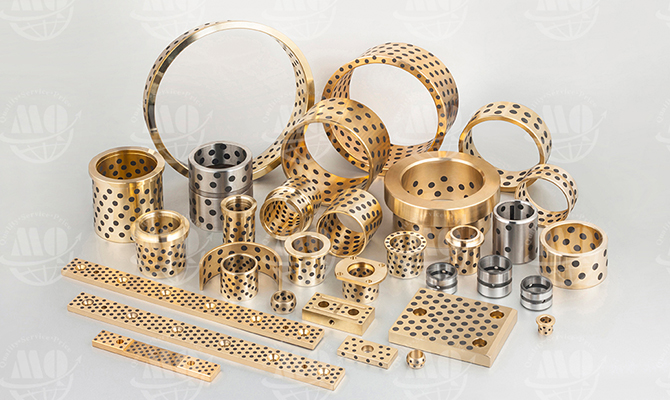

Metal Composite Materials: Metal composite materials usually consist of a metal matrix with a solid lubricant embedded within it. This composite material has good wear resistance and fatigue resistance and is suitable for medium to high load and medium to high speed applications.

Ceramic material: Ceramic material has extremely high hardness, wear resistance and high temperature resistance. Common ceramic materials include alumina, silicon nitride, and boron oxide. They are suitable for applications requiring high speed, high temperature and high corrosion resistance.

Choosing the right oil-free bearing material depends on the specific application requirements, including load, speed, temperature, environmental corrosiveness and other factors. Factors such as cost, availability, and manufacturing processes also need to be considered when selecting materials. The final selection should be determined based on comprehensive evaluation and actual application conditions.

MQ-20

Boundary Lubricating Bushing is made of high quality low-carbon steel as backing,sintered porous bronze layer as the medial layer,then POM+MoS2 mixed with them as the inner lubricating layer; Suitable for reciprocating,rotating and oscillating movements