Bushings are accessories used outside mechanical parts to achieve sealing, wear protection, etc.

Refers to a ring sleeve that acts as a cushion. In the field of valve applications, the bushing is inside the valve cover, and corrosion-resistant materials such as polytetrafluoroethylene or graphite are generally used for sealing.

In the moving parts, the parts are worn out due to long-term friction. When the gap between the shaft and the hole is worn to a certain extent, the parts must be replaced. Therefore, the designer chooses the lower hardness and better wear resistance when designing. The material is the shaft sleeve or bushing, which can reduce the wear of the shaft and the seat. When the shaft sleeve or the sleeve is worn to a certain extent, replace it, which can save the cost of replacing the shaft or the seat.

Generally speaking, the bushing and the seat adopt an interference fit, and the shaft adopts a clearance fit because no matter what is still unavoidable, it can only extend the life, and the shaft parts are relatively easy to process; there are also some new ones. Designers do not like this design, thinking that it increases the cost during manufacturing, but after a period of use, it is still necessary to modify this method when repairing, but the modification is likely to cause the accuracy of the equipment to decrease. The reason is very simple, secondary processing It is not possible to guarantee the position of the center of the seat hole. The sleeve is used to replace the rolling bearing in some places with low speed, high radial load and high clearance requirements (such as camshafts) (in fact, the sleeve is also regarded as a kind of sliding Bearing), the material requires low hardness and wear resistance. The inner hole of the shaft sleeve can be ground and scraped to achieve high matching accuracy. There must be a lubricating oil groove on the inner wall. The lubrication of the shaft sleeve is very important. For dry grinding, the shaft and the shaft The sleeve will be scrapped soon. It is recommended to scrape the inner hole wall of the sleeve during installation so that many small pits can be left. The enhanced lubrication bushing and sleeve are selected according to different industrial and mining conditions. The most important conditions are pressure, speed, pressure-speed product, lubrication state, and load properties. Quick, easy and excellent automatic selection of bushings are included.

It wraps the valve stem, which is worn out and can be replaced easily. If the bushing is not used, the parts are replaced after wear. Therefore, it is to replace the bushing (in the design, the hardness of the bushing is reduced to make it a wear-bearing part in the friction pair). Because of its convenient processing, low replacement cost, and easy replacement. Of course, there is a guiding role, etc., which is second.

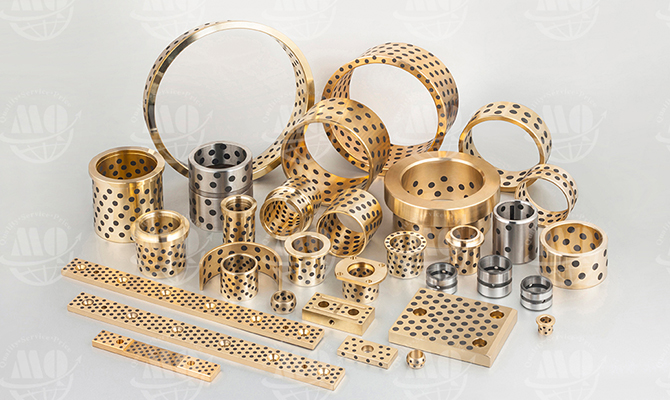

Jiashan Minqin Oilless Bearing Co., Ltd. is an Oilless Bushing Manufacturer, and also has Oilless Sliding Bearing and other products. Welcome to visit our official website.